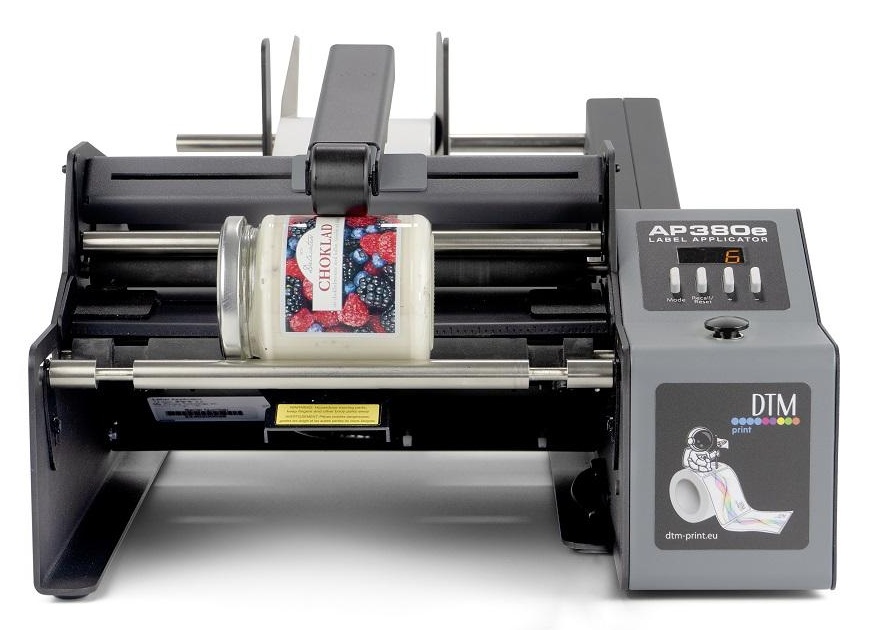

Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators for flat and cylindrical containers are the perfect accessories for virtually any roll-wound label including clear labels, no matter the printing technology.Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators are the most advanced label applicator for the precise semi-automatic labelling of cylindrical containers as well as many tapered containers, including

Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators for flat and cylindrical containers are the perfect accessories for virtually any roll-wound label including clear labels, no matter the printing technology.

Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators are the most advanced label applicator for the precise semi-automatic labelling of cylindrical containers as well as many tapered containers, including bottles, cans, jars and tubes. This model features a built-in liner rewinder, a push button for easier operation by hand and increased speed for the most efficient label application.

How to best operate a label applicator depends on the working environment and work set up. That is different for each application. Sometimes it is more practical to start the labelling process by hand, sometimes better by foot. Keeping that in mind the DTM AP380e now also integrates a push button on the top of the device in addition to the familiar footswitch. The push button allows the user to operate the DTM AP380e by hand.

Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators for flat and cylindrical containers are the perfect accessories for virtually any roll-wound label including clear labels, no matter the printing technology.

Main Features: Quick set-up and easy operation

Integrated label liner rewinder

Operates with push button or footswitch

30% faster than previous models – apply up to 1500 labels per hour

Accurately applies labels to the front and back with variable spacing

5 container roller locations to provide an ideal position for every container

Apply labels quickly and precisely to all types of round containers - The integrated spring-loaded pressure arm ensures that the labels are applied firmly and wrinkle-free. With an AP Series Label Applicator, you can apply labels faster and more accurately, speed up your production and sell more products. Three models are available. AP360e is the base model. It quickly and efficiently applies single labels at a time. The AP380e is our most advanced model. It applies one or two different labels to a single container and has an integrated LED counter. It features a built-in liner rewinder and the fastest speeds for the most efficient label application.

Built-in liner rewinder automatically rewinds the waste liner, keeping the production line clean and organised

Enables two stop modes which stop the container either immediately or delayed after label application.

AP380e is 30% faster than previous models, includes all features of the AP362e as well as an integrated label rewinder.

AP360e/AP362e Label Applicator for Round Containers

Apply labels at speeds of up to 1200 containers/hour.

Primera DTM AP380e & AP363e & AP550e Label Applicator Label Applicators - Technical Specifications:Number of Labels Dispensed per Trigger : 1 or 2 - front and back

Speed : 142 mm/s (5.6"/s) or up to 1,500 containers per hour

Container Shape : Cylindrical and many tapered

Container Diameter : 15 mm - 170 mm (0.6" - 6.7")

Container Width : 25.4 mm - 238 mm (1" - 9.4")

Container Height : 15 mm - 170 mm (0.6 - 6.7")

Label Width : 19 mm - 209 mm (0.75" - 8.25")

Label Height : 19 mm - 609.6 mm (0.75" - 24")

Supply Roll : Up to 203 mm (8") OD with a 50.8 mm to 76.2 mm (2" to 3") ID wound out, die-cut

Label Liner Rewinder : Yes

Label Sensor Type : Mechanical sensor

Indicator Lights : LED display with built-in up/down counter and saved jobs

Controls : Footswitch, Push button, Mode, Recall/Reset, Up, Down

Power Requirements : 100 V - 240 V AC (50/60 Hz), 12 V DC, 5.0 A

Power Consumption : Idle: 1.6 W, Average: 20 W :

Certifications : UL, UL-C, CE, FCC Class A, RoHS, UKCA

Weight : 9.07 kg

Dimensions (W × H × D) : 340 mm × 226 mm × 508 mm

Gap between Labels : Recommended: 3 mm - 6 mm

Label Type : Die cut with or without waste removed; clear labels can be used

Liner Thickness : 50,8 µm - 254 µm (smoothness will affect feeding - a liner that is too slippery or too thin will slip through the drive rollers)

Label + Adhesive Thickness : 127 µm - 381 µm

Wind Direction : Wound out - see copy position chart below (position 3 or 4 for most containers)

What’s in the Box : DTM AP380e Label Applicator, instructions, universal power supply