RJS Printronix SV100 & SV200 SV Series RJS Barcode Scanner &

Verifier of scanner/verifiers by RJS provides both fixed position

scanning and high-speed on-line ANSI method verification of linear

barcodes. This unique instrument can be used for many types of barcode

scanning and/or verifying applications. The SV Series assures that barcode print quality is at an acceptable level. It checks to make sure the

print mechanism has not failed or gone out of adjustment during

operation. It even makes sure that the correct data is encoded and that

the encoded data is in the proper format.

The SV Series assures that barcode print quality is at an acceptable level and reports practically every barcode quality and data parameter known. It offers a turnkey method of monitoring your print process for errors by checking for burned out pixels, ribbon wrinkle and clogged inkjet nozzles.

Features:- Kits available for most popular thermal transfer/direct thermal printer models

- Performs practically every known analysis parameter including ANSI/ISO, traditional and absolute X dimension measurement

- Data match compatibility

- Increment/Decrement capability

- Programmable outputs and serial port for system operation

- Download language

- High-speed or conveyor applications

- Ladder and Picket Fence Code

RJS Printronix SV100 & SV200 SV Series RJS Barcode Scanner & Verifier of scanner/verifiers by RJS provides both fixed position scanning and high-speed on-line ANSI method verification of linear barcodes. This unique instrument can be used for many types of barcode scanning and/or verifying applications. The SV Series assures that barcode print quality is at an acceptable level. It checks to make sure the print mechanism has not failed or gone out of adjustment during operation. It even makes sure that the correct data is encoded and that the encoded data is in the proper format.

RJS Printronix SV100 & SV200 SV Series RJS Barcode Scanner & Verifier are ON-LINE VERIFIERS - The SV Series analyzes and reports virtually every verification parameter known. ANSI and Traditional print quality parameters are transmitted along with decoded data. The reported symbol quality parameters ensure the print method or complete barcode process is optimized. This is important for ISO corrective action procedures, label manufacturing and printing, tracking systems, ink jet applications and more.

RJS Printronix SV100 & SV200 SV Series RJS Barcode Scanner & Verifier are FIXED POSITION SCANNERS - The SV Series can operate as a fixed position scanner. But, since it also provides diagnostic barcode quality information, it can reduce system downtime and save material costs. It does this by isolating the source of the problem. Once the source of the problem is found, it can be corrected before non-readable bar codes are printed and material is wasted.

The diagnostic capability is also useful when installing the scanner or after a conveyor or printer maintenance cycle. The available print quality information gives an indication of first time read rates, optimal scanner alignment, optimal conveyor speed and optimal printer settings and adjustments. In short, everything that is needed to ensure proper set-up of a system.

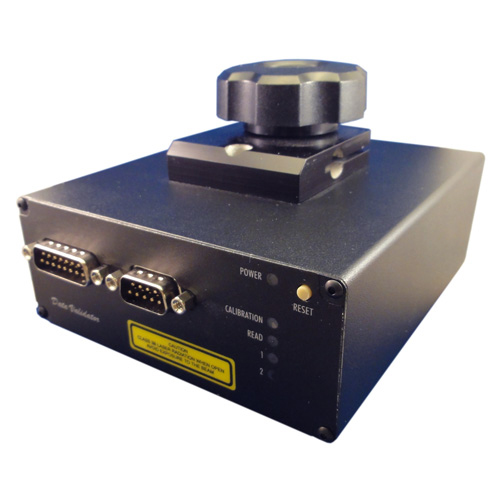

EASY SETUP / FLEXIBLE INTERFACE - The Printronix SV100 & SV200 SV Series RJS Barcode Scanner & Verifier uses a serial port to interface with RJS ScanVision, a PC based software package used for set-up and monitoring. Use ScanVision for SV setup while the scanner/verifier is off line and/or use it for real-time bar code quality analysis while the scanner/verifier is operating.

The unit also incorporates Model SV download language for setup without RJS ScanVision. Five hardware outputs are available via an I/O-Power port for logic operation such as No Read, Poor Quality, Good Quality or Good Read status. Two synchronization inputs are also available for robust No Read evaluations. Two LED’s are available for status indications. The serial port can also be used without ScanVision to provide decoded data and/or bar code analysis information to a host system.