REA VeriMax Mobile is a mobile, offline barcode verification system for 1D and 2D barcodes. With its handy size of 12x12 cm and the possibility to mount a tablet PC directly on the cube, it can be used wherever it is needed - production, laboratory, incoming goods or quality assurance. It checks 1D/2D codes for their readability and content accuracy directly on site - of course in accordance with norms, ISO standards, legal quality and user specifications. REA

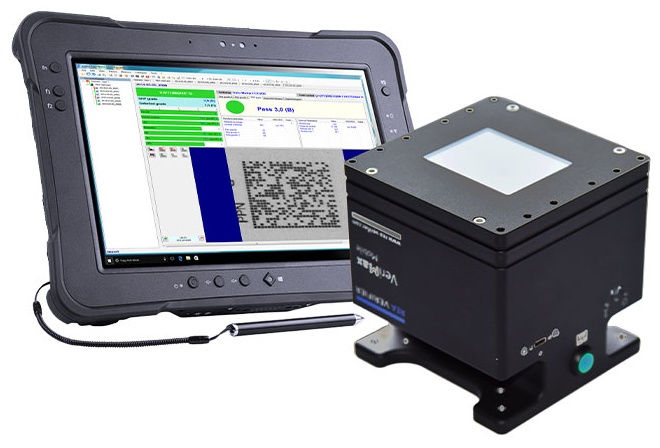

REA VeriMax Mobile is a mobile, offline barcode verification system for 1D and 2D barcodes. With its handy size of 12x12 cm and the possibility to mount a tablet PC directly on the cube, it can be used wherever it is needed - production, laboratory, incoming goods or quality assurance. It checks 1D/2D codes for their readability and content accuracy directly on site - of course in accordance with norms, ISO standards, legal quality and user specifications.

REA VeriMax Mobile is therefore ideal for measuring random samples. The accurate and reproducible measurement results and quality assessments ultimately reduce errors and cut costs. This is because the results of the measurement serve as the basis for optimizing the print quality of the codes. The measured values themselves can be read and managed by the REA VeriMax Mobile software application, which is touchscreen-optimized.

Product Details:

Modern, offline 2D matrix code and 1D barcode verification system

Mobile and flexible use with connection to touch screen optimized tablet PC

Removable top cover plate with replaceable glass plate

Code verification by CMOS camera system

Measurement of optical codes with defined angles, distances and illumination (ISO standard complient)

Darkened measuring chamber to avoid ambient light influences

Main Features:

Barcode verification by a CMOS camera system

Measurement of optical barcodes with defined angles, distances and illuminations (ISO standard-compliant)

Darkened measuring chamber to avoid ambient light influences

Verification according to ISO/IEC 15415 for printed matrix codes and ISO/IEC 15416 for printed barcodes

Verification according to ISO/IEC 29158 (formerly AIM DPM guideline 2006)

Verification in compliance with GS1specifications

Verification of optional parameters to optimize the print process

ISO/IEC 15418 / ANS MH10.8.2 Data structure analysis

Removable top cover plate with replaceable glass plate

Areas of Uses & Applications:

Offline device

Mobile use as stand-alone device or with PC

Verification of 1D/2D barcode quality according to international standards, GS1 and other specifications

Ensuring high first read rates

Capture and recording of all production relevant data in relation to production batches

Advantages:

Specific code selection and configuration for all industries

Can be used as stand-alone device or optionally with connection to 8.4“ or 10.1“ touchscreen-optimized tablet PC

User detaches from stationary workstation and can speed up verification processes

Settings for user-defined profiles for easy operation and faster selection

Device, interface and evaluation software supplied as a package

High measurement accuracy and measurement repeatability due to optimized design

Monitoring of all marking requirements, regardless of the qualification of the personnel used

Multilingual user interface and reports

Technical Data: Measurement accuracy compliance to ISO/IEC 15426-2 and ISO/IEC 15426-1

REA VeriMax Mobile software for Windows included

Housing milled from solid aluminum

Protection class IP54

Red light-LED 660 nm

Illumination angle 45°

Status LED

Power supply via USB port

One button at device to start measurement

Camera resolution 2054 x 1542 pixel

Camera focus and aperture pre-adjusted by factory

Depth of field up to +2mm

Dimensions: 120 x 120 x 120 mm (w/l/h) with buttons 126 mm

Weight: 1560 g

Windows 10 and later, 64-bit

ISO/IEC 15423 : Please note that this performance standard is valid for barcode and matrix codes scanners only. It does not apply to optical measuring instruments like the REA Verifier product range. For Verifiers ISO/IEC 15426-x are the appicable performance standards.

ISO/IEC 15419: Please note that this performance standard is valid for barcode and matrix codes labeling and code generation software as well as for printers printing QR-Codes, Data Matrix Codes and Barcodes.

Barcode Symbologies:2D Matrix Barcodes: ISO/IEC 16022 Data Matrix

ISO/IEC 18004 QR-Code

ISO/IEC 24778 Aztec barCode

ISO/IEC 20830 Han Xin barCode

AIM ISS DotCode

ISO/IEC 15438 PDF417

ISO/IEC 24728 MicroPDF417 barcode

1D Barcodes: ISO/IEC 24723 Composite barCode

ISO/IEC 15420 EAN/UPC (EAN-13, EAN-A, UPC-A, UPC-E und Add-On)

ISO/IEC 15417 Code 128

ISO/IEC 16388 Code 39 (mit PZN und Code 32)

ISO/IEC 16390 Interleaved 2 of 5 (ITF-14)

ISO/IEC 24724 GS1 DataBar

Optional Barcodes: 2/5 3 Bars, 2/5 5 Bars, 2/5 IATA, 2/5 Baggage, 2/5 DHL Express (Frachtpost-Code), Code39 Full ASCII, Code93, MSI, Plessey, Codabar Monarch (18), LAETUS Pharmacode, LAETUS Mini Pharma Code, Russian Crypto Code, China Drug Supervision Code, Japan CVS payment Code, UPU-S10 Postal Codes, DPD Parcel Service

Data structures and barcode properties: GS1 data structures: GS1 DataMatrix, GS1 QR-Code, GS1-128, GS1 Databar, GS1 Composite Code), Crypto Code (GS1 General Specifications)

ISO data structures: ISO/IEC 15418 / ANSI MH10.8.2, ISO/IEC 15459 (part 1 to 8), ISO/IEC 15434 used by Issuing agencies and associations: AIAG, Odette, VDA, EDIFICE, HIBC, DOD, UPU, JEISA, JEITA, IFA)

ISO 28219, ISO 22742, ISO 15394

EFPIA and PPN support for pharmaceutical industry (delegated Act EU 2016/161 and UDI/MDR 2017/745, 2017/746, US DSCSA, Turkey and more, US GUDID alignment (UDI)

DOD MilStd 130 IUID support, AIT (German Armed Forces)

Check digit control settings

Size control settings

Customizable date verification

Optional database (item number verification)

IKEA Data Matrix Code and IKEA interleaved 2 of 5 Code

Evaluation: ISO/IEC 15416 for barcodes, ISO/IEC 15415 for 2D Codes

ISO/IEC 29158 and SAE AS 9132 for DPM

GB/T 14258 (China barcode), ANSI X3.182